Your customers depend on your equipment to deliver dependable performance that increases productivity and uptime, while making it easier to multi-task from sunup to sundown. GGB’s reliable, self-lubricating surface solutions check every one of those boxes, all while extending the service life of your tractors, backhoes, mowers, cultivators, seeders, plows, tillers, planters and more.

Exceeding Expectations

Nobody understands the challenges that agricultural equipment manufacturers like you face better than GGB—from productivity and uptime to all-around dependability, maximum service life and reduced cost of equipment ownership.

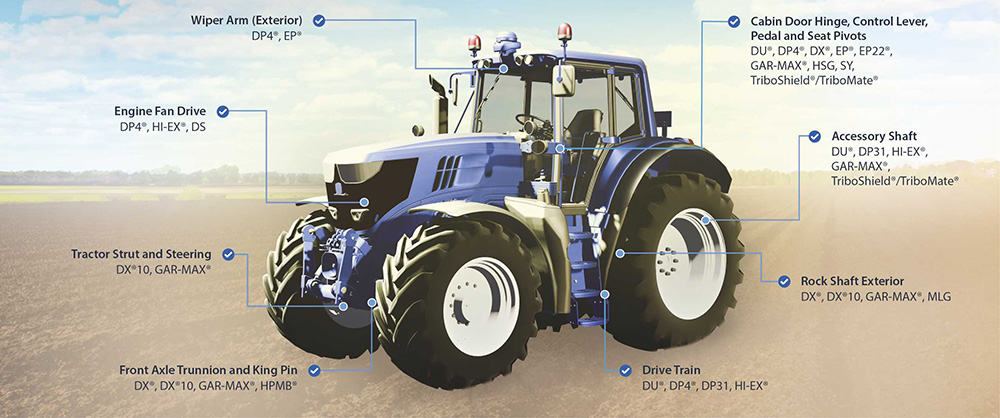

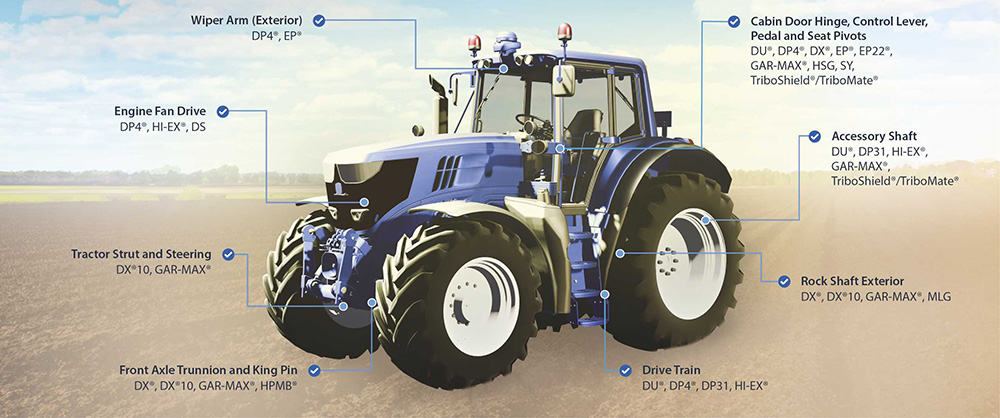

GGB's bearing solutions are used in a wide range of agricultural equipment such as: Tractors, Backhoes, Mowers, Cultivators, Seeders, Harvesters, Sprayers, Plows, Tillers and Planters

Agricultural Applications

- Linkage and Pivot Points

- Hinges

- Pedals

- Steering and Suspension Assemblies

- King Pins

- Hydraulic Cylinders

- Grainhead and Cornhead Reel Systems

- Chaff Discharge

- Auger Heads

- Doors and Chutes

- Boom Pivots

Eliminate Grease to Reduce Maintenance

- Self-lubricating GGB surface solutions are ideal for applications with inadequate or no lubrication.

Increase Performance and Extend Service Life

- Superior wear resistance and high shock load capacity result in extended service life, while low friction properties reduce power losses for improved equipment performance.

Reduce Costs

- GGB bearings eliminate the need for hardening and machining grease paths, while also offering space and weight savings for simplified assembly.

Lower Environmental Impact

- Greaseless, lead-free GGB surface solutions comply with increasingly stringent environmental regulations.

Need a replacement solution?

Our self-lubricating agricultural bearings are resistant to erosion damage and provide excellent resistance to wear, chemicals, cavitation, flow erosion and fatigue. Since lubrication is eliminated, equipment no longer needs to be taken out of operation to be serviced, saving you time and money.