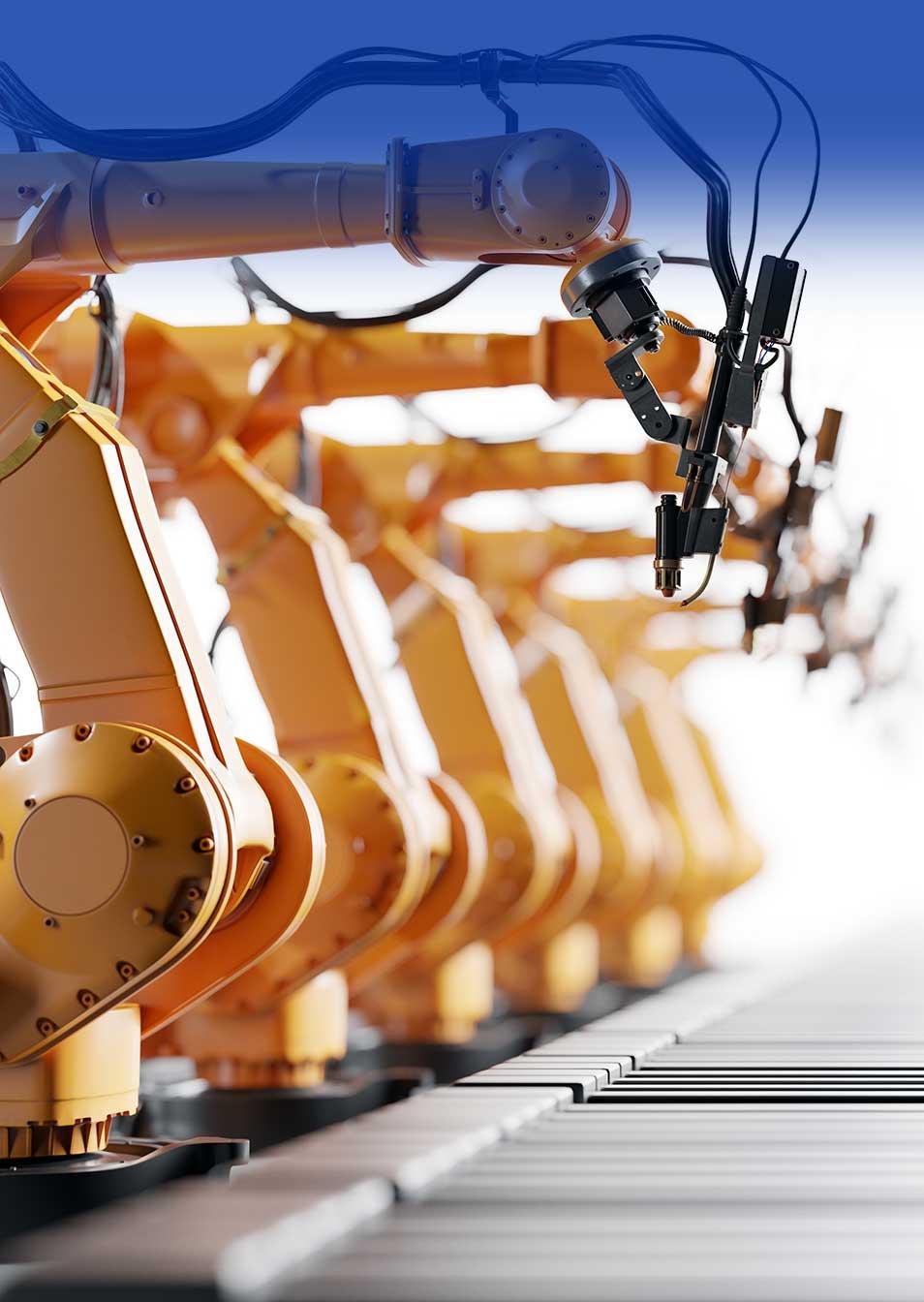

Uptime is a key challenge that all industrial manufacturers continually face—no matter the industry: chemicals, metals, plastics, pharma, food and beverage and much more. At GGB, we know short lead times, quick turnarounds and minimal downtime are critical to your operation. And that’s where we come in.

Unique applications require unique solutions

When you need reliable, maintenance-free bearings that can stand up to demanding industrial environments, you can count on GGB to deliver innovative solutions designed to keep your equipment running efficiently for longer—across a broad range of uses and applications:

- Awnings

- Bending Presses

- Cable Winding Devices

- Elevators

- Escalators

- Food processing equipment

- Furniture

- Heat-Treating Units

- Industrial applications on both land and underwater

- Industrial solder machines

- Injection molding

- Lifts

- Machine Tools

- Manufacturing Equipment

- Material Handling

- Multi-Ram Press Guides

- Packaging Equipment

- Power Tools

- And Many more...

Increase Performance and Extend Service Life

- Superior wear resistance and high shock load capacity result in extended service life, while low friction properties reduce power losses for improved equipment performance.

Reduce Costs

- GGB surface solutions eliminate the need for hardening and machining grease paths, while also offering space and weight savings for simplified assembly.

- Low coefficients of friction eliminate the need for lubrication, while providing smooth operation, reducing wear and extending service life.

Lower Environmental Impact

- Greaseless, lead-free GGB surface solutions comply with increasingly stringent environmental regulations to restrict the use of hazardous materials in electrical and electronic equipment.

Reliable in any situation, on any application

Our self-lubricating surface engineering solutions for industrial applications are custom designed to meet a wide range of industrial applications so that you can significantly reduce, mitigate and even prevent downtime.