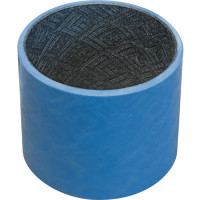

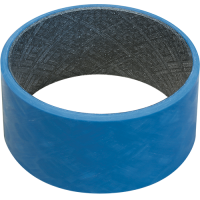

- Machinable inner and outer diameters for superior application precision, circularity and cylindricity tolerances

- Pre-machined high precision HPMB bearings available for immediate installation

- High precision through easy single point machining of the bearing liner, on-site prior to installation

- Superior precision achieved with post-installation (inner diameter tolerance IT7 attainable) single point machining of the bearing liner

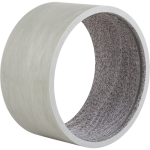

- High load capacity

- Excellent shock and edge loading capacity

- Low friction with negligible stick-slip

- Low wear rate for extended bearing life

- Excellent corrosion resistance

- Dimensionally stable - very low water absorption, low swelling

- Environmentally friendly grease-free operation

- Tested by Powertech Test to evaluate performance of self-lubricated bushings in wicket gate applications

- Tested acc. to ASTM E595/ECSS-Q-ST-70-02C - Outgassing properties of materials used in Spacecraft equipment

AVAILABILITY

Bearing forms made to order: finished cylindrical bushings, pre-machined cylindrical bushings, flanged cylindrical bushings (subject to design review)