GGB's Metal-Polymer Bearing Solution for Food Processing Equipment

Bearing Application Requirements

Equipment in the food processing industry must comply with stringent hygienic standards, so the bearings must be able to resist corrosion, chemical attack and frequent wash downs with water and cleaning solvents.

GGB Industrial Bearing Solution

DP4-B lead-free, metal-polymer bearings are used to guide the slicing equipment at strokes of 210 mm and 420 mm, a frequency of 30 slices per minute and continuous operation for 16 to 24 hours a day.

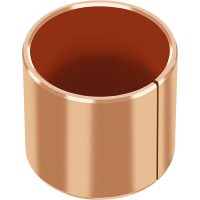

The structure of the composite bearings consists of a corrosion-resistant bronze backing onto which is bonded a porous bronze sinter layer, impregnated and overlaid with a filled PTFE sliding layer. This provides good wear resistance and low friction performance under a wide range of load, speed and temperature conditions.

GGB Industrial Bearings - Benefits

The benefits from using DP4-B composite bearings include:

- Superior corrosion resistance to frequent wash downs from the bronze backing

- Low friction and good wear resistance performance in dry and lubricated operating conditions

- Suitability for intermittent operation under reciprocating or oscillating movements

- Long life and trouble-free performance

- Lead-free in compliance with RoHS and WEEE regulations