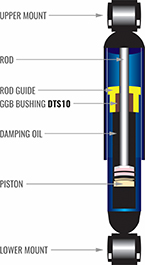

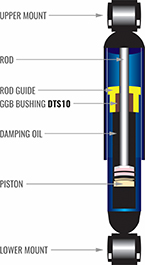

The GGB bushing is located inside the strut and is mounted in the rod guide assembly.

The function of the bush is two-fold.

- Support the radial loads that are applied to the strut from the suspension, loads that vary considerably during cornering, acceleration and braking and also from the road topography under all types of road conditions

- Allow the sliding movement of the piston rod to which is fixed the piston that dampens the vibrations during the extension and compression cycles of the shock.

After analysis of the higher load conditions and taking into account the restriction of not increasing the size of the bushing due to weight and dimensional constraints whilst still maintaining overall life performance, it quickly became apparent that a new bearing solution was required.

To meet these requirements, the metal-polymer GGB DTS10® is the ideal bearing solution for this new generation of struts as its unique composite structure offers:

- A homogenous anti-friction overlay enriched with PTFE and wear resistant fillers with a minimum thickness above the bronze layer of 0.1mm

- Steel backing for high mechanical strength

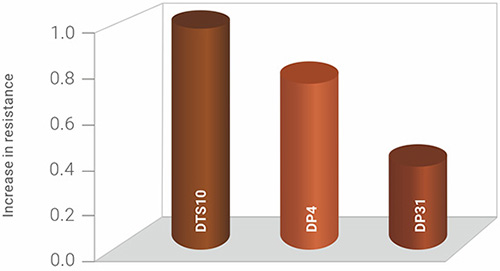

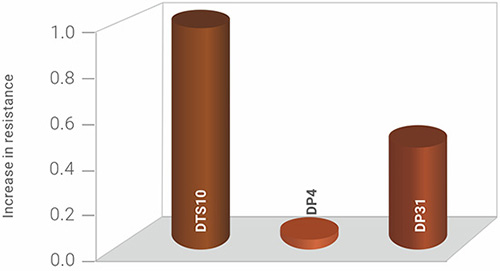

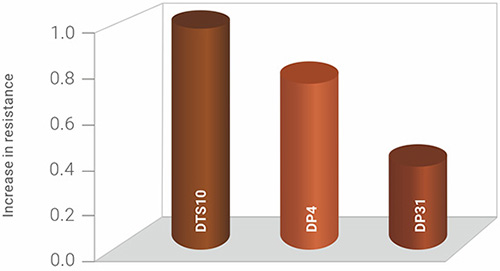

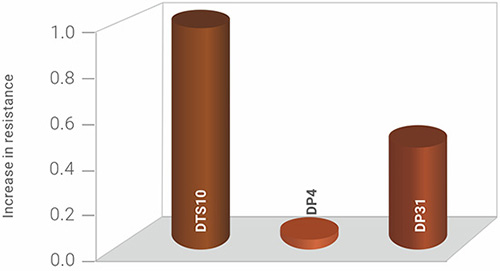

As indicated in the DTS10 Product Brochure, the superior tribological performance of DTS10 compared to other products has been evaluated by multiple tribological trials on test benches in our Research and Development laboratories.

Relative Lubricated Wear Resistance

Relative Hydrofatigue Resistance

Trials in the field have further given a confirmation of the benefits of GGB DTS10® in strut applications which are:

Improved strut response

- Constant low friction performance and negligible stick-slip effects from the PTFE enriched overlay.

Longer endurance performance

- Superior life performance with a homogenous bearing overlay containing wear resistant additives,

- Potential better acceptance of edge loading on the bush due to bending of the rod under heavy loads from an increased overlay thickness above the bronze layer.

For more information on GGB DTS10® and how it can be incorporated into your high performance suspension project, please visit the product page, download the brochure or contact us directly via marketing@ggbearings.com